This past weekend I did some work in the yard, preparing it for the inevitable winter. One of the things that has long been on the back burner was to put up some lights in the back yard. When it is dark out, it can be very treacherous making one’s way around on the snow and ice in the dark. Several weeks ago Mark gave me some outdoor lights, a gesture that proved just enough of a spark to ignite a smoldering idea.

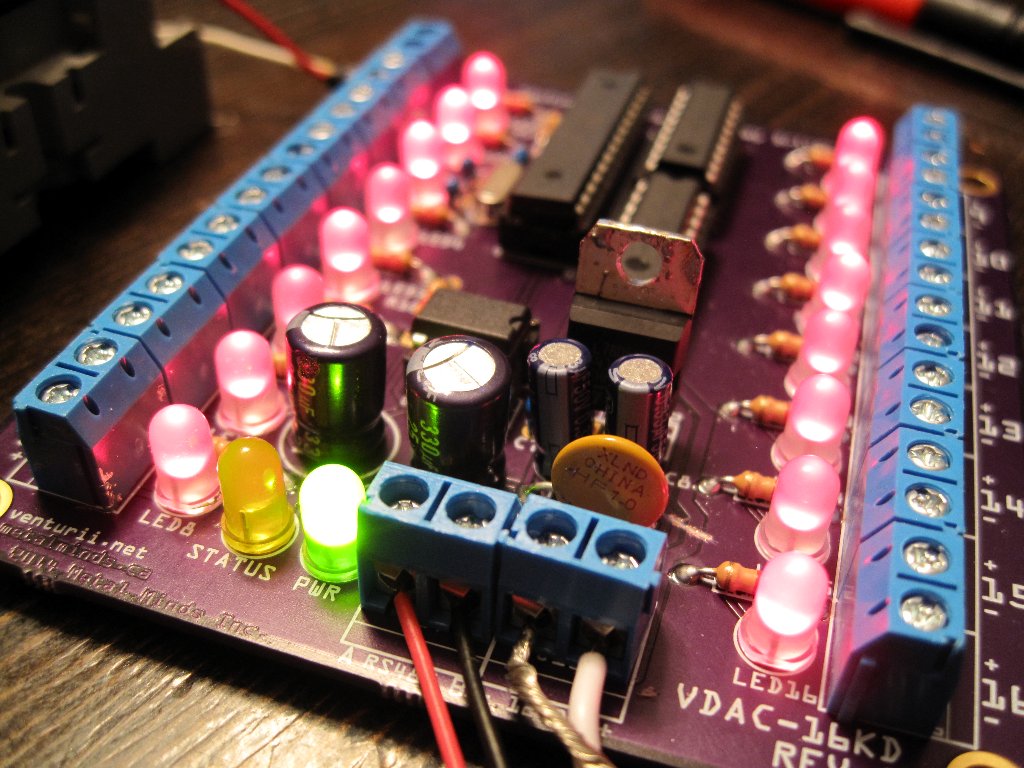

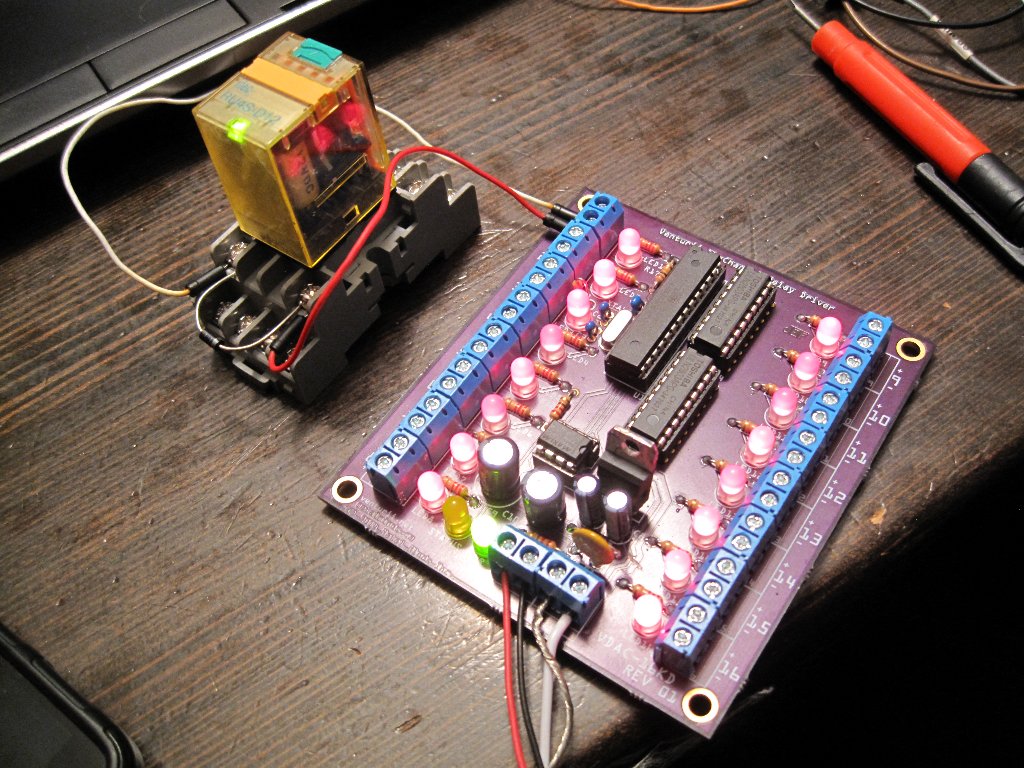

The lights seen on the stairs above are waterproof LED strips I bought from Aliexpress. So far, they’ve worked very well having survived a summer and a fall, complete with more than a couple of rainfalls. The winter may prove another story, but that will come in good time. Seen above at 16/255 power output from a prototype Venturii VDAC controller, they are more than bright enough to see in the dark. At full power, they are almost too bright. Even as it is, the light reflected off the deck surface from the LED strips shines on my bedroom ceiling if the Venetian blinds are tilted the right way.

Mark gave me five of these moon shaped cup lights, and after much debating their destination, I realized that I had five fence posts along the darkest corner of the back yard. I mounted one and powered it off a battery to see if I liked the location, light cast, and ambiance. It was definitely a winner. With an 11 watt bulb in each, at about 6′ off the ground, they light up the area very well in the dark. Full power is definitely not needed on these either, so I took advantage of a surplus of MOSFET drivers at my disposal and wired them up with a home run from each light. This basically gives me the option of individually setting the intensity of each lamp individually. All manner of light patterns, sequences and uses come to mind and will be put into play in good time, but for the moment they are running paralleled off a single IRL540 MOSFET. Even with 5 x 11w = 55w @ 12VDC or 4.583 amps, the driver is cool to the touch. Data from a photocell capturing the ambient light level outside determines the output level of these lights, as they ramp up to full brightness as the sun goes down, and taper off in the morning as the first light of a new day dawns. The effect is nothing short of beautiful as they cast a warm half-moon-shaped glow on the ground and wooden fence boards. Tiny shapes cut into the top of each fixture allow tiny beams of light to escape onto the walls of the house and the deck, drawing the mind’s curiosity, imagination, and fascination to their incandescent glow.

Elsewhere in my tiny back yard I have a clump of trees enclosed in decorative interlocking bricks. Mark was also generous in providing dozens of low voltage outdoor fixtures apart from the cup lights seen above. As a test, I installed a number of them in the tree pit to see which style might become my favorite. Mounted therein are three style: Two silver bollard-style fixtures with MR-11 lamps inside, shining upwards onto a chunk of glass that disperses the light in all directions, a Path Light style fixture and a traditional Pagoda style light all sit nestled within the decorative brick wall of my tree pit. I have to admit, each light has it’s own appeal, and a clear winner is tough to pick.